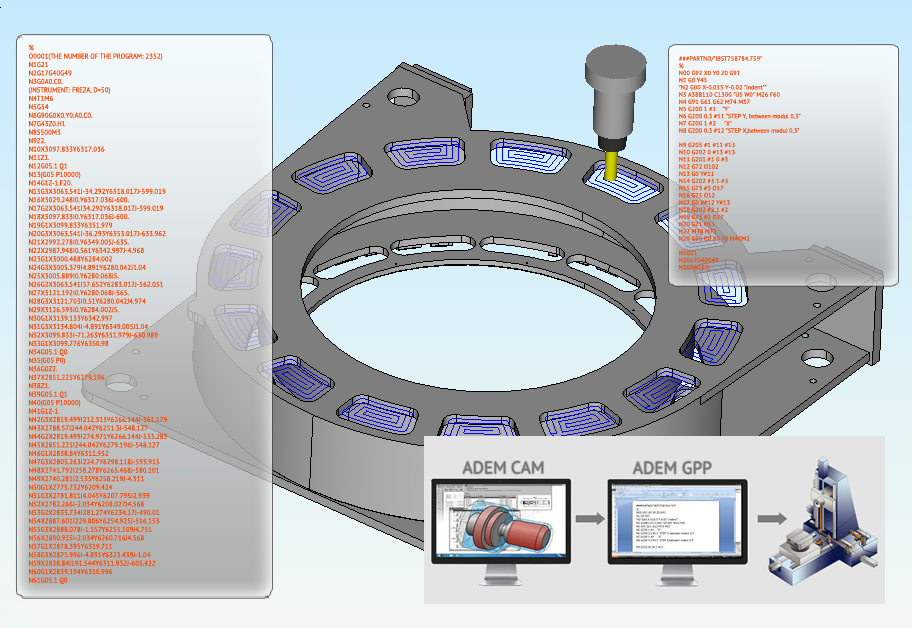

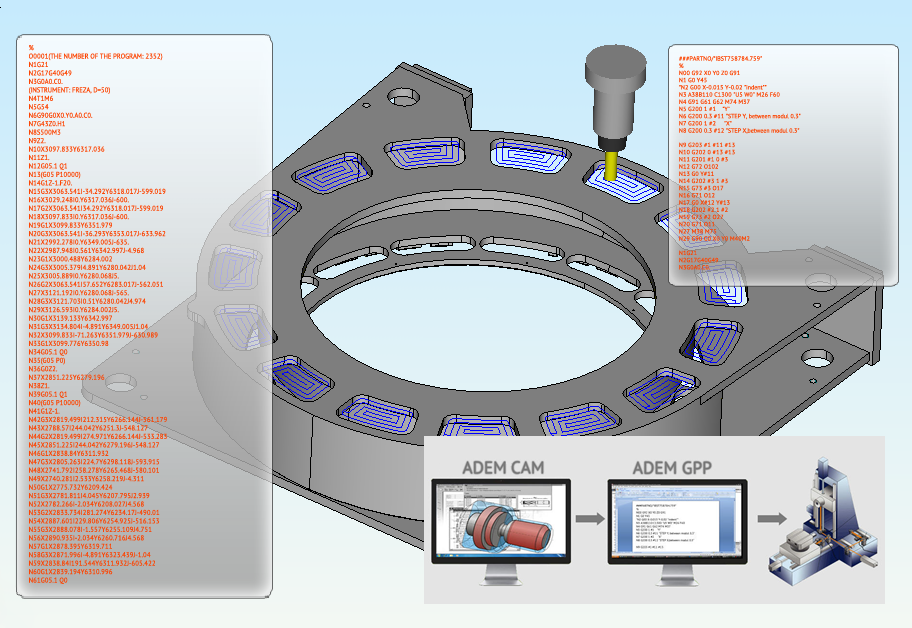

ADEM CAM

ADEM CAM is a module for creating control programs for all types of CNC machines and systems, including multi-channel equipment. Provides simultaneous control (maximum) of 5 independent axes.

Similar design tools for various types of processing allow you to obtain control programs for flat and volume milling, turning and combined turning and milling, as well as contour cutting, within the same module.

One software product allows you to provide the need for a CAM system for specialists of various departments - instrumental, experimental and serial production.

ADEM CAM is used in the following fields: aviation, nuclear, aerospace, machine building, electrical and instrument making and other industries.

In addition to creating control programs, ADEM CAM prepares data on processing technology (tooling data, material consumption rates and time, etc.) for transfer to process design systems (ADEM CAPP, VERTICAL. Integration with other software products is also possible).

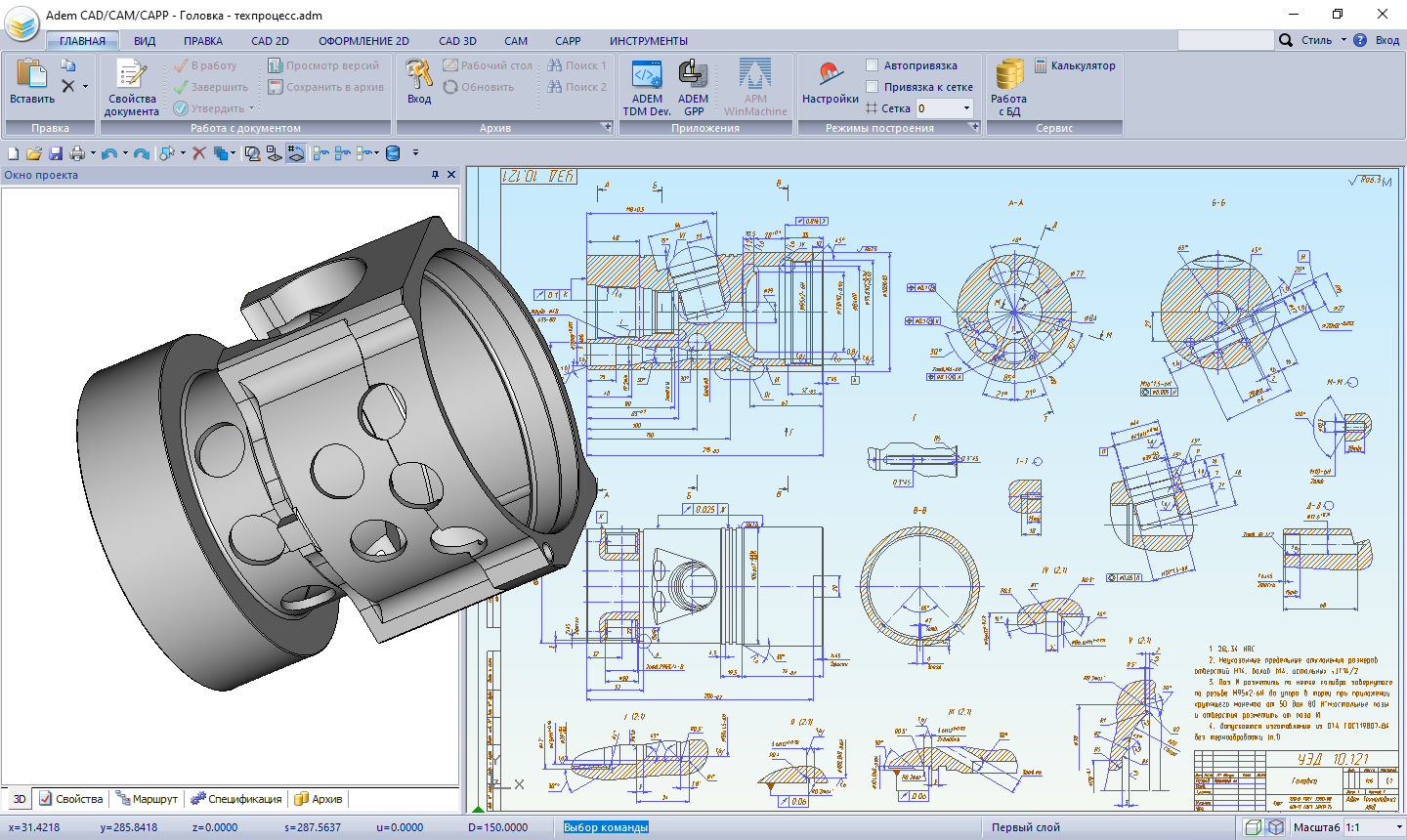

Read directly and integrate with CAD systems

Import/export of graphic information from any CAD systems is implemented through standard formats, or through a direct transfer interface (direct reading of models in * .dxf, * .dwg, * .sat, * .iges, * .stl, * .step, * .prt, * .catpart, * .ipt, * .sldprt, * .x_t, * .par, * .m3d).

The ADEM CAM for KOMPAS-3D application is an example of successful integration of the ADEM CAM module functionality into the workspace KOMPAS-3D.

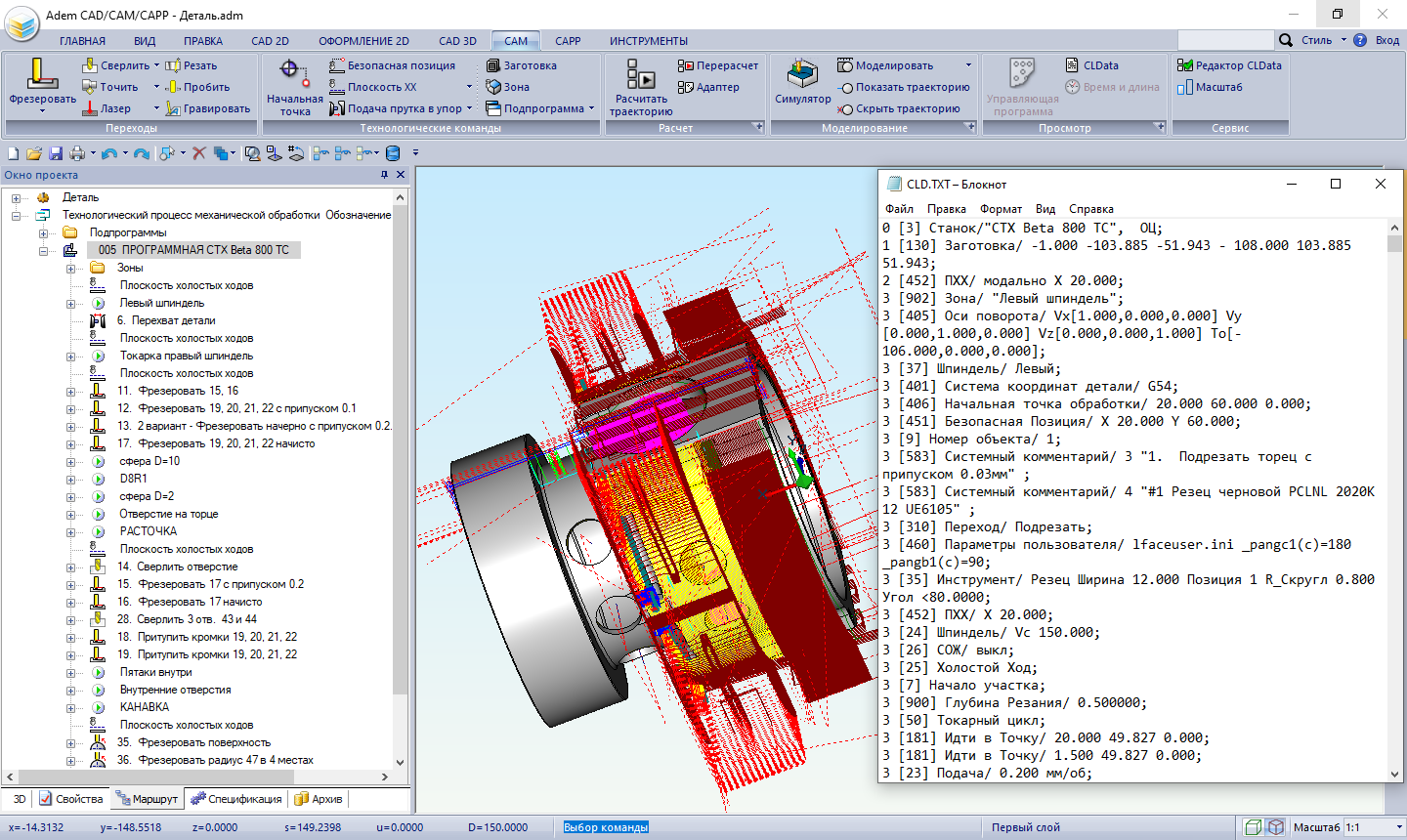

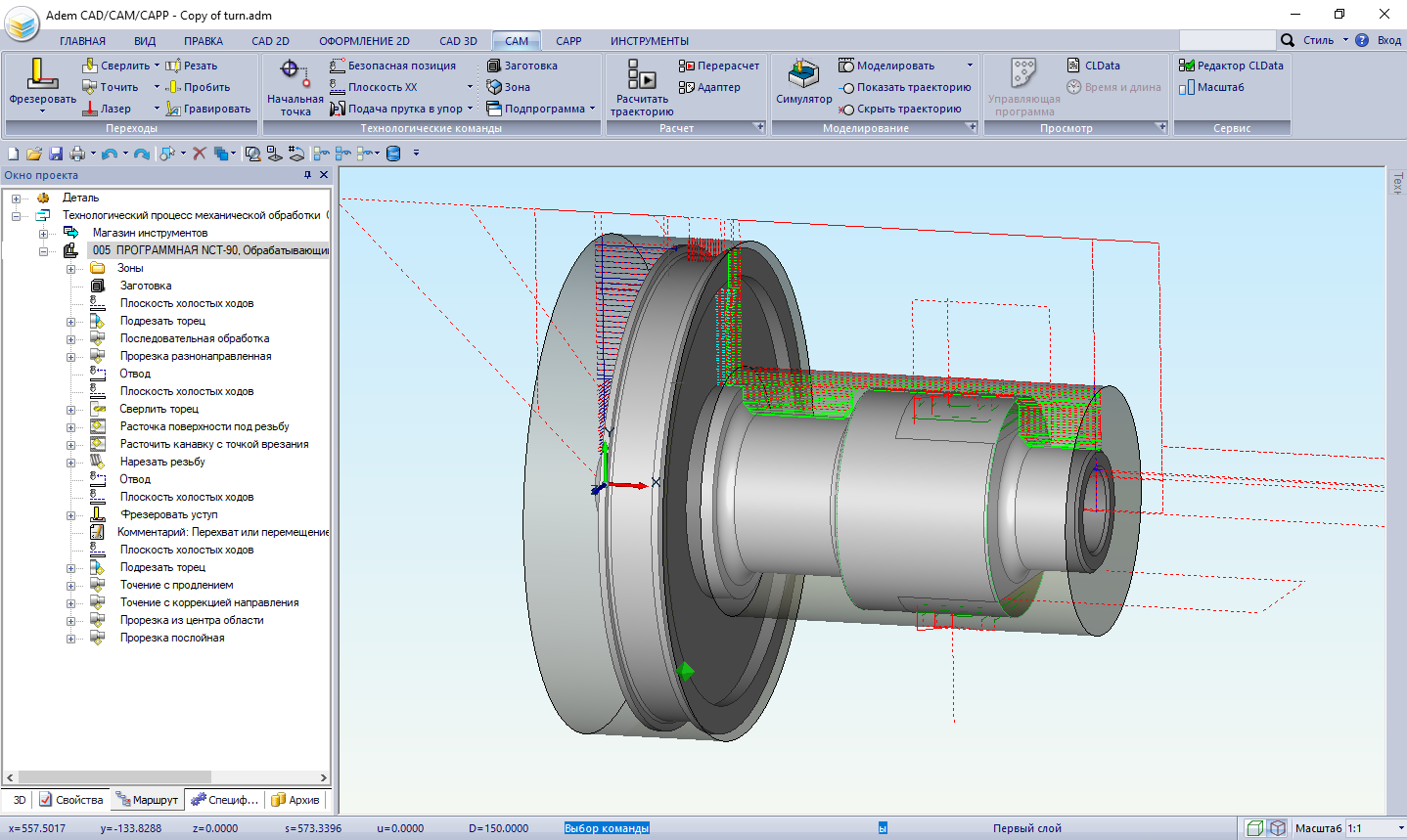

One route for any NC machining

A single space for designing all treatments performed on NC equipment. Universal tools and methods of work for designing machining for all modern types of equipment: multi-axis milling machines, turning-cutting machining centers, multi-channel equipment, multi-link robots, etc.

Benefits of ADEM CAM

- Large choice of processing strategies.

- Selection of cutting modes and their optimization taking into account the dynamic characteristics of the machine and stabilization of the load of the machine drives.

- Increase tool performance and durability.

- Original algorithms for optimizing cutting processes, reducing processing time by 25-50%.

- Monitoring the condition of the workpiece at each processing stage.

- Extensive selection and automatic adjustment of tool cut-in patterns.

- Simple and efficient control of tool position/orientation in multi-axis machining.

- Automatic generation of process elements based on geometric information.

- Calculation of running time of each tool and calculation of total machine time taking into account all tool movements.

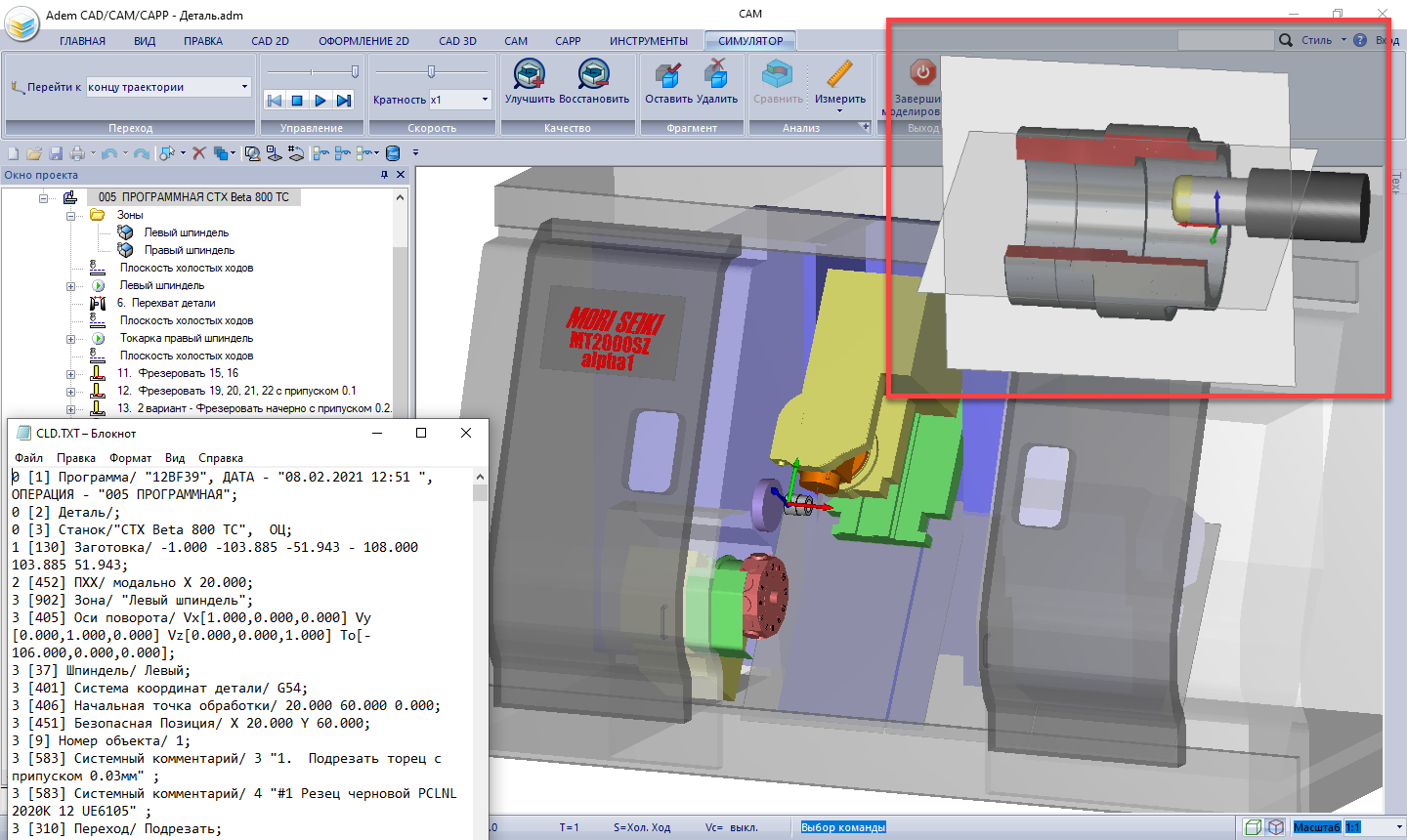

Simulation of processing

- Built-in ADEM processing simulator designed for dynamic visualization of the product processing with material removal.

- Modeling can be carried out in various modes: with the display of the workpiece, part, tool, tooling, equipment elements, etc.

- Simulation results can be used to compare processing results with the design model.

- Monitoring of collisions of machine units, tools and accessories during machining simulation.

- Comparison of the processed part with its mathematical model, visualization of gouging and flaws with quantitative assessment of the removed and abandoned material.

- Saving intermediate processing simulation results in *.stl format, allows modeling of the entire part processing route on CNC equipment in several Software operations.

- Integration with third-party simulation and processing verification systems.

Support for any NC system

Own tools for creating post-processors to adapt the received processing routes to the customer's equipment fleet.

ADEM CAM post-processors allow you to receive Control Programs for all the most popular CNC systems - Fanuc, Heidenhain, Sinumerik, Mazak, Okuma, etc., including support for processing cycles.

Interaction with all program-controlled tools of the machine (supply of billet, inter-ception, trap for parts, change of pallets, etc.). Control programs received in ADEM CAM allow you to realize the full potential of the equipment.

Supported languages

polish

german

korean

french

english

russian

turkish

System Requirements

Recommended System Requirements:

- Processor: 4-core Intel Core i5 or higher

- Memory: 4GB RAM or more

- Video adapter: preferably NVIDIA with at least 52 MB of VRAM. (At least 1024 MB of VRAM is recommended for the 3D module, for the rest of the modules, any size of video memory is suitable, starting with 256 MB.)

- Disk: After unpacking and installation, the ADEM system occupies about 6GB on the hard disk

- Input device: Keyboard 116 keys (with an additional numeric keyboard), three-button mouse (with a wheel)

- Operating system: Windows 7 SP1 and above, Windows 8, Windows 10